Currently Out Of Stock

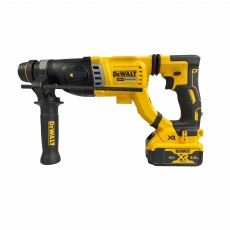

Cordless SDS Plus Hammers

SDS Plus hammer drills are designed to be able to efficiently drill through tough materials like concrete, bricks and other masonry materials. Cordless SDS Plus hammer drills allow you to move freely around the home or the jobsite and are perfect when you need that extra power but don’t want to deal with a trailing power cable. Just like a hammer drill, SDS plus drills combine the rotary motion of a standard drill with a hammering action but, unlike a hammer drill, the hammering action is provided by a piston in the gear box that directly strikes the back of the drill bit. The impact force of a rotary hammer is expressed in energy (joules). The higher the number of joules, the faster and more efficient the heavy drilling jobs will be.

SDS stands for Slotted Drive System or Slotted Drive Shaft and refers to how the SDS chucks and drill bits produce the extra torque and force needed to drill through heavier duty materials, like brickwork and metal. The SDS Plus (or SDS+) drill is the most popular type of SDS drill — and the names are often used interchangeably. SDS Max drills take even larger drill bits and are used for even heavier-duty work. We stock a wide range of SDS hammer drills from the tool manufacturers you know and trust, including Makita, Bosch and DeWalt SDS drills.

What is an SDS Plus drill?

SDS, which stands for Slotted Drive System, refers to the way the SDS chuck and SDS drill bits work, and how they deliver the extra force and torque needed to drill through heavy-duty materials. In an SDS drill you’ll find a special chuck with a hammer mechanism that acts like a piston, firing the SDS drill bit backwards and forwards. Along the shaft of the SDS drill bits there are indentations that fit between two ball bearings within the chuck allowing the hammer action to be delivered. This delivers a more powerful and precise force than a standard hammer drill, making them a great choice for fast and effective drilling into tough materials like masonry and steel.

What is the difference between SDS Plus & SDS Max?

SDS (Slotted Drive System or Slotted Drive Shaft) refers to how the chucks in SDS drills produce the extra force to drill through heavier duty materials. The terms SDS and SDS Plus (SDS+) are often used interchangeably. SDS Plus is the most popular type of SDS drill, they will use drill bits from as small as 4.5mm up to a maximum of around 30mm. SDS Max drill bit start at around 12mm and can go up to around 45mm. SDS+ bits have two open and two closed grooves and are held in place by two locking ball bearings inside the machine. SDS Max drills are used for even heavier-duty work and their bits have three open grooves with a locking segment. For heavy-duty work like demolition, you’ll be better off with extra power and strength of SDS Max. For smaller projects, an SDS Plus will get the job done.

Can you use an SDS drill as a screwdriver?

Yes, they can but they are not ideal for this application. SDS Drills generally come in two mode and three mode variants. Two mode SDS Drill have the option to turn of the rotary hammer function and switch to rotary only. This allows an SDS drill to be used to drill other materials such as wood and plastic as well as driving screws. You would also normally need an SDS+ chuck adaptor and a ½ inch keyed or keyless chuck to allow the machine to accept standard drill and screwdriver bits. Ideally for a drill to be used as a screwdriver, it must have two features; variable speed, so that you can slow the speed to an appropriate rotational speed for driving screws, and a clutch, that will sense tension once the screw is driven into place. Without the clutch the drill will continue spinning after driving the screw into the surface, stripping the head of the screw and making it difficult to drive the screw further or remove it. For a versatile drill that can drive screws while also delivering hammer action for drilling, consider a cordless combi drill.

Can you use an SDS drill to Chisel?

Most SDS Max drills and all three mode SDS+ drills have the option to turn the rotation of the machine off. This stops the chuck from turning but does not stop the hammer action. While in this setting, both chisels and points can be placed into the machine and will then allow them to carry out a more demolition based job. SDS+ drill would generally be used for very light demolition tasks such as brick and tile removal. While SDS Max drills with their heavier Joule ratings can be used for bigger jobs such as removal of walls and concrete.

Do SDS drill bits fit all drills?

It is not advisable to use an SDS drill bit in a standard drill or vice versa. The chuck on a standard rotary or hammer drill is not designed for SDS drill bits. Using an ill-fitting bit can cause the bit to come loose, damage the drill and affect the quality of your work. We have a wide range of SDS+ drill bits and SDS+ accessory sets from leading brands including Makita and DeWalt that are designed to fit your SDS+ drill perfectly. If you’re using a SDS Max drill, checkout our range of SDS Max drill bits and accessory sets.