DEWALT DCN680N 18V XR Brushless 18G Brad Nailer BODY ONLY

DEWALT DCN680N 18V XR Brushless 18G Brad Nailer BODY ONLY

Why Not Add

VAT (£2.50 ex VAT)

VAT (£13.15 ex VAT)

VAT (£7.21 ex VAT)

VAT (£8.89 ex VAT)

What’s Included

- Belt Hook

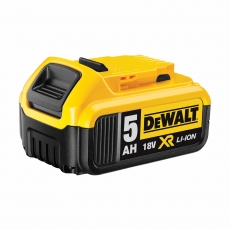

- This is a Body Only machine, which is not supplied with a battery or charger.

- This item may be supplied in unbranded packaging

- Number of Batteries Supplied: 0

- Voltage: 18v

- Type: Brushless

Product Overview

Unleash cordless precision with the DEWALT DCN680N brad nailer. This powerful dewalt nail gun tackles decorative molding, casings, crown, and shoe molding with ease, thanks to its ability to drive 18-gauge brads from 15mm to 54mm. Ditch the cumbersome hose and compressor the DCN680N runs on a DEWALT 18V XR battery, offering cordless convenience without sacrificing performance. Enjoy pneumatic-like features like tool-free depth adjustment and jam release, plus the flexibility to choose between sequential or contact firing.

Part No: DCN680N-XJ(DEWPDCN680N)

Features & Benefits

- Depth of drive can be easily adjusted using the thumb wheel depth adjuster

- Sequential mode allows for precision placement and the bump operating mode provides the user with production speed of up to 4 nails per second

- Mechanical rather than gas operation offers low running costs and consistent performance at low temperatures

- Compact, lightweight and ergonomic design makes the tool easy and comfortable to use but durable enough for worksite environment

- BRUSHLESS motor offers runtime that cannot be beaten in a compact package

- Tool free stall / jam clearance minimises down time

- Trigger and contact trip lock-off and prevent accidental dis-charge of fastener

Technical Specification

- Voltage: 18 v

- Nail Diameter: 1.2 mm

- Nail Length: 15 - 54 mm

- Magazine Angle: 0°

- Magazine Capacity: Up to 110 Nails

- Fastener Type: 18 Ga

- Trigger Type: Bump and Sequential

- Weight: 2.6 kg

- Integrated Belt Hook: Yes

- Jam Clearing: Yes

- Height: 302 mm

- Width: 96 mm

Reviews

FAQs

Cordless Nail Guns and Staplers are incredibly useful but choosing the right model for you can be tricky. There are lots of options available, both in terms of the tools themselves and the fasteners they use.

The first thing to think about is the power source for your tool. Will it use a battery, in the same way as other power tools, be air-powered via a compressor or utilise gas fuel cells? Historically, battery powered tools have tended to struggle when driving longer length fasteners into hardwoods, but with Makita developing new 40v options, that is changing. Nailers which use Gas Fuel Cells are often capable of working with a larger nail range, but the cells have a specific shelf life and will require replacement.

Another thing to think about is the magazine capacity; the larger the capacity, the more nails you can fire between magazine changes.

The first thing to consider is what you need it to do. There are different kinds of Nailers – first fix machines use larger nails and are designed to add rigidity, to a project. Second fix, or ‘finishing’ Nailers use smaller, more discreet nails for work where a clean finish is required, such as door frames. These can vary in cost, performance and in the type of nail they use. One way to pick the right tool is to consider the work you’ll be doing and the nail size you most use, then pick a nail gun to suit the job, as different types of nailguns will use different nail lengths. For instance, a Brad Nailer, which is a type of finishing Nailgun, will typically use a nail of 15-40mm length, while a Framing Nailer will usually use a nail between 50 and 90mm long.

That depends what sort of projects you’ll be doing and where you need your nails to go. The terms ‘straight’ and ‘angled’ refer to the magazine; an angled tool will enable you to work in corners, or anywhere else you would be working at an angle. They’re great for working in tight spaces and can usually hold longer nails because of the size of their magazines. In addition, they tend to be lighter and easier to store than a straight nailer.

Straight nailers use thinner nails – they can’t go below 16 Gauge – and tend to be heavier more difficult to transport than angled nailers, but are frequently cheaper to buy.

Brushed motors use carbon brushes to transfer power from the fixed part of the motor to the rotor. This creates a reliable and relatively inexpensive motor, but brushed motors do require regular maintenance, in order to either clean the brushes or replace them as they wear out. A brushless motor, by contrast, uses a magnet mounted on the rotor to generate the power and electrical switching to perform the function carried out by the brushes. The additional complexity of the motor’s working means that brushless motors are usually more expensive than brushed.

The voltage of your machine will be partially determined by how it drives nails. For instance, a Paslode Framing Nailer which uses a gas fuel cell to fire each nail might have a battery with only 7.4v, while a Makita XGT Brad Nailer, which is designed to used on jobsites and relies on its battery entirely, is a 40v tool. Consider the work you’ll be doing with your Nailgun or Stapler and how that fits in with the other items in your tool set; this will help you to select the tool which best meets your needs.

Delivery & Returns

Warranty

Related Products

VAT (£41.67 ex VAT)

VAT (£37.02 ex VAT)

VAT (£230.25 ex VAT)

VAT (£35.57 ex VAT)

VAT (£159.32 ex VAT)

VAT (£268.53 ex VAT)

VAT (£390.26 ex VAT)

VAT (£10.82 ex VAT)

VAT (£697.49 ex VAT)

VAT (£261.93 ex VAT)

VAT (£335.91 ex VAT)

VAT (£576.60 ex VAT)

VAT (£469.63 ex VAT)

VAT (£445.01 ex VAT)

VAT (£13.15 ex VAT)

VAT (£7.21 ex VAT)

VAT (£8.89 ex VAT)