What is an impact driver used for?

An impact driver is an incredibly powerful power tool that’s well worth having in your toolkit. If you find that your standard drill isn’t forceful enough to drive screws and fasteners, an impact driver is a go to tool when a standard drill just isn’t powerful enough.

Ideal for driving screws into hard wood using impressive torque, impact drivers have become a popular choice for both professional tradesmen and DIY lovers.

Read on to learn more about impact drivers, how they work, their benefits, and how to choose the best model for your needs.

How does an impact driver work?

When looking at an impact driver, you may notice that it looks quite similar to a standard drill. However, it’s what’s inside that makes an impact driver a superior choice.

Using rotational force (also known as torque) and concussive impacts, an impact driver can effortlessly hammer in a screw while it's spinning. But how does this work?

- When the trigger is activated, the motor turns the chuck, introducing the initial rotation. At this point, the impact driver works like a standard drill.

- When the impact driver meets resistance, whether this be from a long screw or a tough material, the impact mechanism is activated.

- Impact drivers use a spring-loaded hammer and anvil system, where the rotational force compresses a spring behind the hammer as resistance increases.

- When the spring tension reaches its maximum, it releases, causing the hammer to move past the anvil and deliver a rapid rotational striking movement.

- This striking movement applies constant extra torque to the fastener so you don’t have to, minimising wrist strain and user fatigue.

The rotational force of an impact driver is its best quality, allowing users to sink and secure large fasteners quickly with minimal effort.

Comparing impact drivers with other tools

Is there ever a scenario where a standard drill is a better choice? Let’s take a look at how different power tools compare with an impact driver.

Impact drivers vs drill drivers

Impact drivers and drill drivers have very similar purposes, and they can both be used for drilling, driving, and screwdriving.

However, impact drivers deliver higher torque which makes them better suited for driving screws, bolts, and fasteners into tough materials. In comparison, a drill driver is best for drilling holes and light screwdriving tasks as they don’t deliver as much torque.

It’s also worth noting that using an impact driver requires less effort as it handles the impact action, whereas a drill driver requires a constant and steady force from the user.

Impact drivers vs hammer drills

Impact drivers and hammer drills are both extremely powerful and useful tools, but their purposes and uses differ.

Hammer drills should be used if you need to drill into masonry like brick, stone, and concrete. They can deliver high torque, but their linear impact direction is designed to break up hard masonry materials. This differs from the purpose of an impact driver, which is made to drive long fasteners into wood and metal with extremely high torque and rotational force.

How to choose the right tool for the job

Faced with a task, but unsure whether an impact driver, hammer drill, or drill driver is the best choice? Here are some task examples to help you decide:

Best tasks for impact drivers:

- Driving long fasteners like screws and lag bolts

- Assembly work that requires a lot of screwdriving

- High resistance fastening applications (to minimise wrist strain)

Best tasks for drill drivers:

- Light to medium duty drilling and screwdriving tasks

- Tasks that require a mix of drilling and driving

Best tasks for hammer drills

- Drilling into masonry like brick, concrete, or stone

- Masonry chiselling (On SDS hammer drills with rotation stop)

What tasks can an impact driver carry out?

One of the best benefits of impact drivers is their versatility and ability to carry out a variety of tasks with precision, power, and ease. Here are just a few things you can do with a high quality impact driver in hand:

![]()

-

Driving long screws into wood

Whether you’re fixing some decking, fencing, or framing, the high torque and rotational mechanism of an impact driver can easily and effectively sink long screws. With no need to apply constant and excessive pressure, you can save effort and protect yourself from bit slippage.

![]()

-

Screwing into dense materials

Hardwood and treated timber stand no chance against an impact driver. Their impressive force means they can screw fasteners into rigid woods and make light work of framing and carpentry projects.

![]()

-

Installing lag bolts and coach screws

Heavy duty fasteners like lag bolts and coach screws require a high volume of torque to be securely positioned into materials. Impact drivers are much more efficient at doing this than a standard drill or manual wrench due to their short bursts of high torque.

![]()

-

Driving self-tapping screws into metal

Ideal for HVAC installations, impact drivers can turn the tricky task of driving self-tapping screws into metal into something effortless. With controlled bursts of torque, an impact driver can reduce the risk of stripping and threading while minimising physical discomfort.

![]()

-

Working in tight spaces

If you work in small spaces, an impact driver can be useful. It doesn’t take much effort to operate, making overhead and awkward angle tasks a breeze with its constant pressure.

![]()

-

Screwdriving tasks

The speed, torque, and simple operation of an impact driver make this tool an essential addition to any repetitive screwdriving job. Its efficiency means you can get the job done quicker without the risk of fatigue or discomfort.

The best impact drivers from ToolStore UK

Ready to upgrade your tool collection with an impact driver? Take a look at the most popular impact drivers in our range, manufactured by popular, trusted brands like DeWalt and Makita.

DeWalt DCF887N

![]()

![]()

- Features: High power brushless motor, three professional-grade motor speeds, ‘PrecisionDrive’ mode, compact body, built-in LED ‘Halo’ work light ring, quick-change chuck

- Weight: 0.94kg

- Speed: Up to 3,800 ipm (impacts per minute)

- Torque: Up to 205Nm (suited for heavy duty applications)

- Battery compatibility: Compatible with all DeWalt 18v XR battery packs

- Best for: Heavy duty domestic, commercial, and industrial applications for tradespeople

Makita DTD153Z

![]()

![]()

- Features: Brushless motor for efficiency and long lifespan, variable speed control trigger, forward/reverse rotation, compact, twin LED lights, electric brake, ergonomic soft grip, one-touch sliding chuck, belt hook

- Weight: 1.5kg

- Speed: Up to 2,900 ipm (impacts per minute)

- Torque: Up to 170Nm

- Battery compatibility: Compatible with all Makita 18v LXT battery packs

- Best for: Light to medium duty tasks for professionals and DIY enthusiasts

Who could benefit from an impact driver?

An impact driver is a worthwhile upgrade for professional tradespeople, DIYers, and anyone looking to replace their basic drill.

Professionals can enjoy a high-torque power tool that is as efficient as it is ergonomic, reducing fatigue and strain on busy worksites. An impact driver is also equally beneficial for residential DIY projects with its impressive power, and can be used for constructing sheds, laying decking, and more.

If you simply want to upgrade your old drill, an impact driver can offer you the industry’s best in power, speed, and control, taking your projects from tiring and time consuming to speedy, precise, and efficient.

Tips for getting the best out of your impact driver

Once you’ve found the best impact driver in our range, it’s essential to take care of it so you can benefit from its maximum lifespan and efficiency. Here’s how:

-

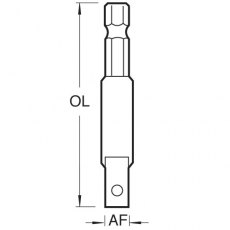

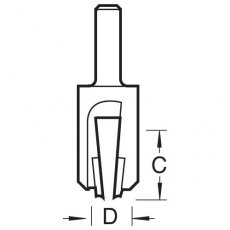

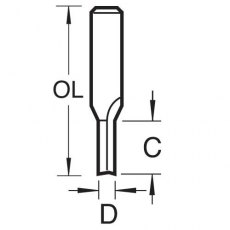

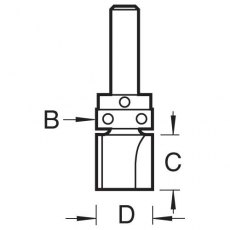

Make sure you use the right impact driver bits

Many users forget that impact drivers need impact driver bits. These bits are specifically designed for use with an impact driver and are manufactured to withstand high levels of torque and impact. They are highly durable, suited for tough materials, and reduce the risk of stripping and damage.

-

Choose the right speed for your material

Impact drivers are versatile and offer intuitive speed controls, so make sure to use lower speeds for more delicate or fragile materials like softwoods and plastics, and use higher speeds for hardwoods, metals, or where you need to fix long, heavy duty fasteners. Using the wrong speed can result in damaged material or a subpar fix.

-

Don’t skip maintenance

Like any piece of equipment, your impact driver will need regular cleaning and checks for best performance. Check the chuck and vents for dust build up, conduct regular inspections for worn or loose components, and lubricate moving parts as needed for smooth operation.

-

Minimise unnecessary impact

Remember that your impact driver can generate torque by itself — you don’t have to. Putting unnecessary force on your impact driver can cause wear and tear to the anvil and hammer, leading to a shorter lifespan. You can always pre-drill pilot holes if required to reduce strain on your impact driver.

Shop DeWalt and Makita impact drivers at ToolStore UK

If you’d like to tackle your projects with ease in less time, look no further than our collection of DeWalt and Makita impact drivers. All of our products come with a 1 year warranty as standard for your peace of mind, with an option to extend.

Enjoy free delivery on all orders over £55 and next day delivery for just £1.95 when you make an order before 4pm Monday to Thursday.

Need a hand choosing the best impact driver for you? Don’t hesitate to contact us or call our team on 03330 043 777, and we will be more than happy to help.

Impact driver FAQs

Can I use an impact driver as a screwdriver?

Yes, this is what they are designed for! An impact driver uses high torque, impact action, and rotation to insert screws into tough materials like hardwood, plastic, steel, and even iron.

Why can’t you drill with an impact driver?

It’s best to use a drill driver or a hammer drill if you need to drill holes during a task. Impact drivers use a rapid hammering action, which means they often create inaccurate holes. Drilling holes using an impact driver can also damage the drill bit.

When should you use an impact driver?

An impact driver is the best power tool to use if you need to drive long screws, bolts, and other fasteners into tough, rigid materials. You should also use an impact driver if you struggle with wrist strain while working on projects, as their consistent force requires very little user effort.

- When the trigger is activated, the motor turns the chuck, introducing the initial rotation. At this point, the impact driver works like a standard drill.

- 1st July 2025